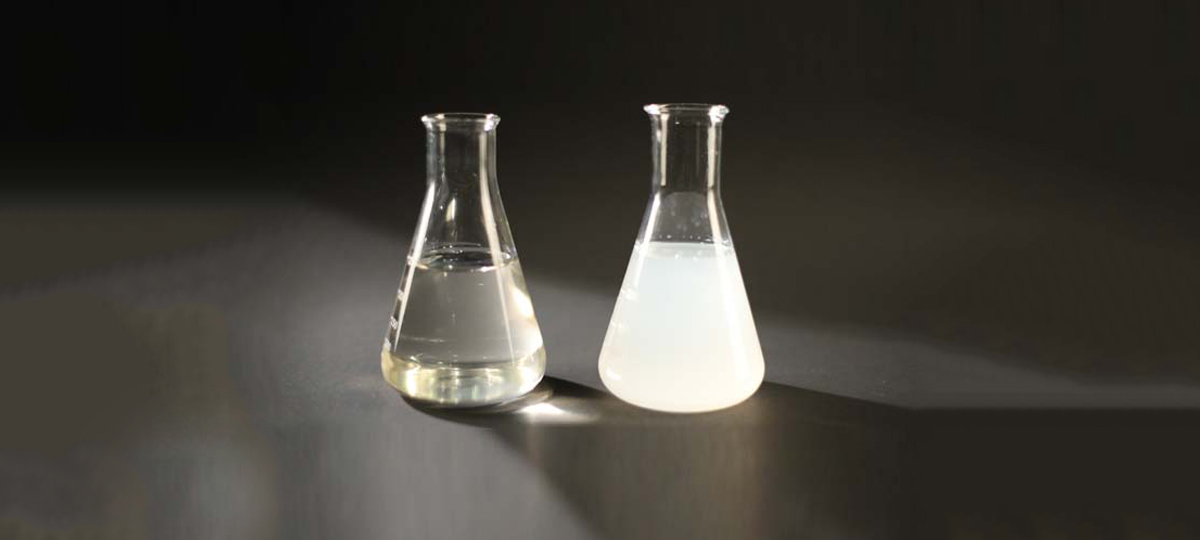

Alkaline Sodium Silicate Liquid is a viscous, clear to slightly hazy aqueous solution composed primarily of sodium oxide (Na₂O) and silica (SiO₂) with a high molar ratio of Na₂O, making it strongly alkaline in nature. It is manufactured by dissolving sodium silicate glass in hot water under controlled conditions.

This liquid silicate is widely used for its excellent adhesive, binding, deflocculating, and corrosion-inhibiting properties. Its alkaline pH and high reactivity make it suitable for a wide range of industrial applications.

| Product Group | Properties | Range |

|---|---|---|

| Sodium Silicate Liquid (Alkaline Grade) | ||

| Wt. Ratio of Na2O: SiO2 | 1:1.50 to 2.80 | |

| Specific Gravity / Baume | 1.20 - 1.70 / 38 - 62 Be | |

| Total Soluble Solids | 34 to 57% | |

| Na2O | 9 to 22% | |

| SiO2 | 25 to 37% |

Applications

- Detergent Industry : As a builder and corrosion inhibitor in laundry and cleaning formulations.

- Adhesives & Binders : Used in paperboard lamination, carton sealing, and refractory materials.

- Welding Electrode Manufacturing : Acts as a binder and flux for coating electrodes.

- Chemical Processing : Intermediate in the production of silica gels and zeolites.

- Construction : As a concrete hardener, sealant, and fire-resistant coating.

- Foundry : Used as a core binder in mold making.

Features

- Strong alkalinity and high reactivity

- Excellent binding and adhesive properties

- Environmentally safe and non-toxic when handled properly

- Available in different Na₂O:SiO₂ molar ratios (commonly 2.0 – 3.5)

- Customizable viscosity and concentration as per industry needs

Specifications

- Appearance : Clear to slightly hazy liquid

- Molar Ratio (Na₂O:SiO₂) : 2.0 – 3.5

- pH : 11.5 – 13.5

- Density : 1.35 – 1.55 g/cm³ (varies with concentration)

- Solubility : Fully miscible in water

Storage & Handling

Store in a tightly sealed container in a dry, well-ventilated area. Avoid contact with acids and moisture. Use standard PPE including gloves and eye protection during handling.